-

By Admin

-

March 14, 2024

- 0 Comment

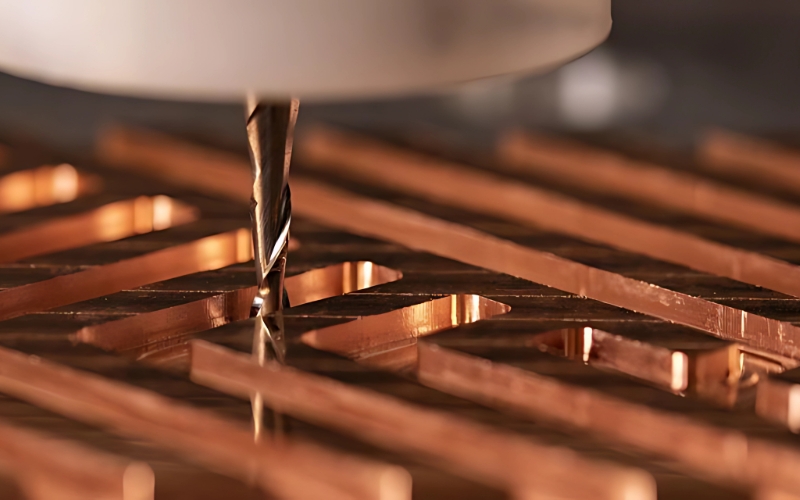

Copper Components Engineered for Excellence

Introduction

Copper is One of the Most Versatile and Reliable Materials used in Various Industries, from Electronics to Construction. Its Excellent Conductivity, Durability, and Corrosion Resistance Make it an Ideal Choice for Manufacturing Precision Components. In This Blog, We Explore How Copper Components are Engineered for Excellence and Why they are Essential for High-Performance Applications.

Why Copper is the Preferred Choice for Engineering?

Copper Offers Several Advantages Over Other Metals, Including:

- Superior Electrical Conductivity: Essential for Wiring and Circuit Boards.

- High Thermal Conductivity: Ideal for Heat Exchangers and Cooling Systems.

- Corrosion Resistance: Ensures Long-Lasting Performance in Harsh Environments.

- Malleability and Ductility: Allows for Easy Shaping into Complex Designs.

Key Applications of Copper Components

1. Electrical and Electronics Industry

Copper is Widely used in Electrical Wiring, Connectors, and Circuit Boards due to its Unmatched Conductivity and Reliability. It Ensures Efficient Power Transmission with Minimal Energy Loss.

2. Automotive and Aerospace

Copper Components Play a Vital Role in Battery Terminals, Radiators, and Braking Systems. Its Ability to Withstand Extreme Temperatures makes it a Key Material in High-Performance Vehicles and Aircraft.

3. Industrial Machinery

Gears, Bearings, and Bushings made from Copper Alloys Provide Excellent Wear Resistance, Making them Ideal for Heavy-Duty Industrial Applications.

4. Renewable Energy Systems

Solar Panels and Wind Turbines Rely on Copper for Efficient Power Generation and Transmission, Supporting the Shift Towards Sustainable Energy Solutions.

Manufacturing Processes for Copper Components

Copper Components are Engineered using Advanced Manufacturing Techniques such as:

- CNC Machining: Ensures Precise Shaping and Detailing.

- Forging and Casting: Enhances Strength and Durability.

- Electroplating: Improves Corrosion Resistance and Surface Finish.

- 3D Printing: Enables Rapid Prototyping and Customization.

Conclusion

Copper Components are the Backbone of many High-Performance Industries, Offering Unmatched Efficiency, Durability, and Sustainability. Whether in Electronics, Automotive, or Industrial Applications, Copper Remains a Top Choice for Engineered Excellence.

Looking for High-Quality Copper Components? Get in Touch with Us Today!